Pickup truck production lines and assembly lines are used to assemble and produce body-on-frame pickup trucks, non-body-on-frame pickup trucks, new energy electric pickup trucks, and more.The equipment comprises a comprehensive production line consisting of various automated systems, including automated conveyor lines, parts assembly lines, workshop packaging lines, chassis assembly lines, interior assembly lines, final assembly lines, inspection lines, and rainproof seal testing lines.The equipment is also available for export to overseas markets.For more information about the equipment, please contact our engineers. We can provide customized designs tailored to your production needs.

Equipment:

- Overhead or ground-mounted flatbed conveyors for body wiring harness, interior, and chassis assembly

- Underground plate chain assembly lines- Powertrain and rear axle assembly lines

- Automatic conveyor and hoisting mechanisms

- Door and instrument panel lines, tire conveyor lines, and auxiliary equipment

- Inspection lines, rainproof seal testing, and light channel inspection lines

- Rework equipment, lifting platforms, and paint booths

- Production support equipment: generators, air compressors, filling equipment, parts logistics, assembly and maintenance tools, and centralized fluid supply.

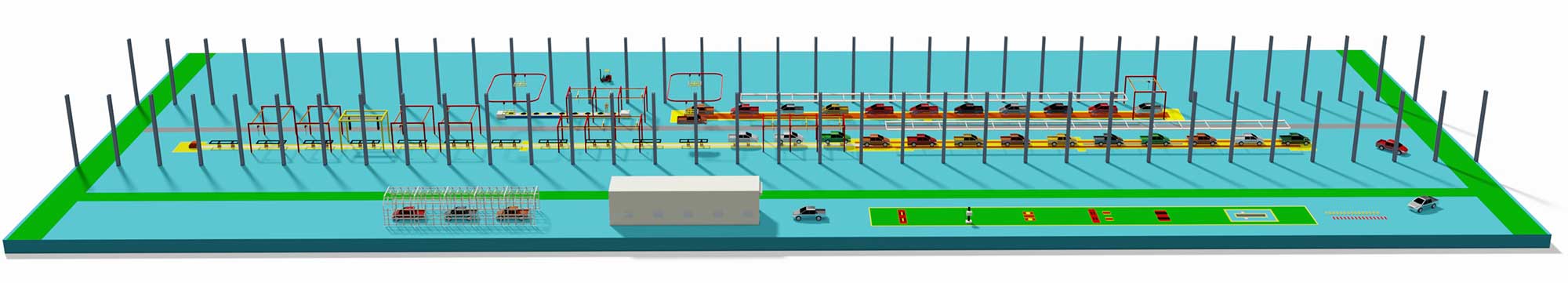

Equipment DEMO - Pickup SKD Production Line

Equipment graphic introduction

The pickup truck production line is a manufacturing process specifically used to produce pickup trucks. It covers the entire process from raw material processing, body welding, assembly, to final quality inspection and delivery.

(1) Raw material processing: The starting point of the production line is the processing of raw materials, including cutting and stamping of steel. Advanced cutting machinery and stamping equipment can efficiently process steel plates into various parts required for pickup trucks.

(2) Body welding: The processed raw materials are sent to the welding workshop, where an automated robotic welding system is used to weld the various metal parts into the body structure. This process requires high precision and high speed to ensure the quality of welding.

(3) Body painting: The welded body will then enter the paint shop. Here, the body will go through multiple steps such as cleaning, phosphating, primer spraying, topcoat spraying and drying to ensure that the body has good corrosion resistance and beautiful appearance.

(4) Final assembly: The painted body will be sent to the final assembly line, which is the core part of the pickup truck production line. Here, workers or robots will assemble various components such as the engine, seats, dashboard, tires, etc. onto the body. The final assembly line usually includes multiple stations, each responsible for different assembly tasks.

(5) Inspection and debugging: The assembled pickup trucks will enter the inspection area and undergo a series of performance tests and safety inspections, including brake tests, lighting tests, and emission tests, to ensure that each pickup truck meets factory standards.

(6) Delivery: Pickup trucks that have passed the final inspection will be transported to the warehouse to wait for shipment to dealers or direct delivery to customers.

The entire pickup truck production line is a highly automated and information-based system. It ensures the production efficiency and product quality of pickup trucks through sophisticated equipment and strict process control. With the development of technology, more and more intelligent technologies are being applied to pickup truck production lines, such as the Internet of Things, big data analysis, and artificial intelligence.